SENTINEL® One

Premium Connection

Main features and benefits

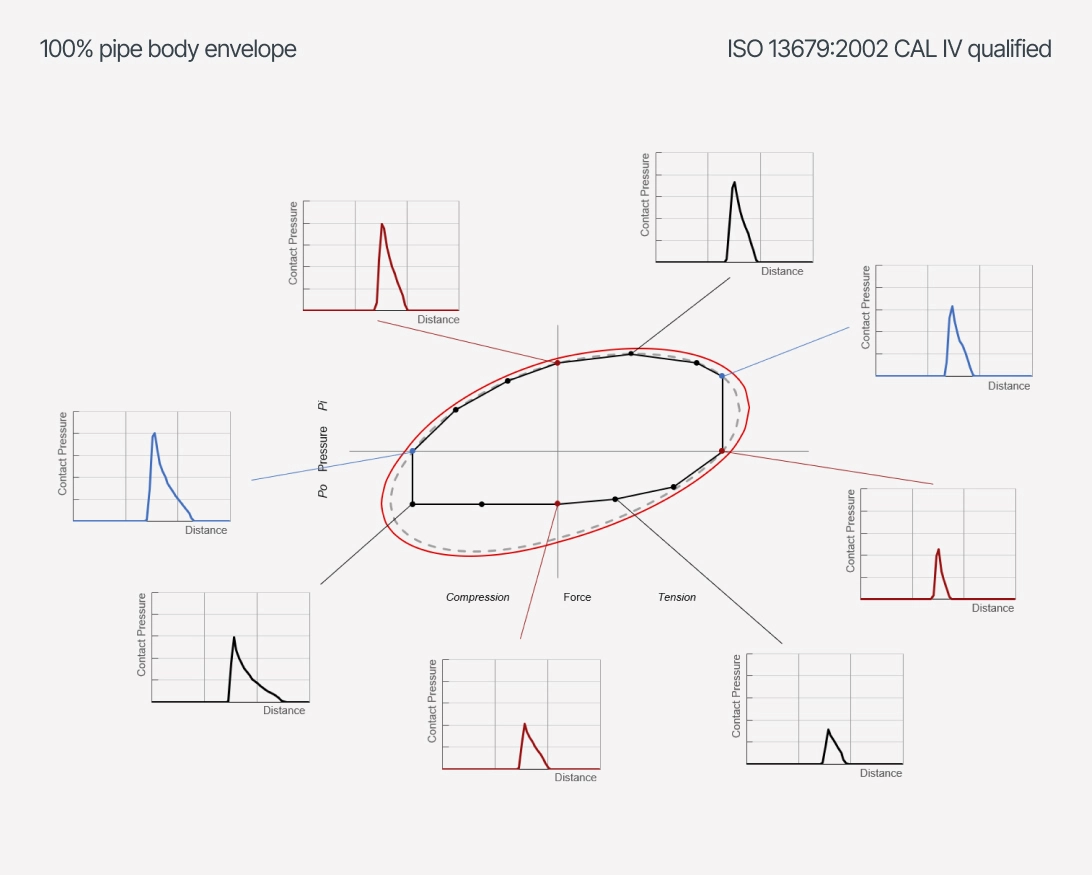

100% compression rating

Ease of stabbing and running

Full in-house manufacturing

Discover why we stand out

-

Reliability

Reliability at the heart of design criteria. SENTINEL® One has been full-scale tested as per ISO 13679:2002 to the most stringent connection assessment level (CAL IV).

It has been designed and tested on CRA materials including Super Duplex and Alloy 28, showing outstanding performance in terms of sealability and galling resistance.

-

Manufacturing process

Complete control of the manufacturing process.

From steel melting to threading, delivery and field service, efficiency, and flexibility across the value chain.

-

Delivery

Excellence in delivery of downhole tubular technologies with unmatched customer service.

From our global manufacturing centers to the customer well site, TUBACEX is a leader in the supply of CRA OCTG solutions for critical environments.

Seal design

- Cone to cone axial and hoop seal

- Verified gas tight seal capabilities

- Optimized torque shoulder area to maximize compression rating (100%)

Thread design

- Negative load flank hook design

- Positive stabbing flank

- Reduced gap to withstand compression loads

Product Line

| OD | Weight Range | Thread Pitch |

| 4½” | 10.5 to 23.7 ppf | 6 TPI |

| 5” | 15 to 24.1 ppf | 5 TPI |

| 5½” | 15.5 to 29.7 ppf | 5 TPI |

| 6⅝” | 20 to 36.7 ppf | 5 TPI |

| 7” | 26 to 38 ppf | 5 TPI |

| 7⅝” | 29.7 to 47.1 ppf | 5 TPI |

Applications

- Production Tubing and Casing

- HP/HT Gas and Oil Wells

- CO2 Injections Wells - EOR

- Carbon Capture and Storage Injections

- Horizontal and Deep Wells

- Geothermal Wells

End-finish Options

- Rig-ready storage and running system: Specially coated box + Engineered Eco lubricant (reduced environmental footprint)

- Standard CRA end-finish: Cu-platted box + API-modified™

By your side

Contact us